Optimal Timing for Epoxy Flooring Installation

Epoxy flooring installation timing is crucial for achieving optimal results. Factors such as temperature, humidity, and surface preparation significantly influence the curing process and durability of the coating. Properly timed installation ensures a long-lasting, seamless finish that resists wear and environmental damage.

Epoxy coatings perform best when applied in temperatures between 60°F and 85°F, ensuring proper curing and adhesion.

Low humidity levels are essential during installation to prevent bubbles and curing issues. High humidity can cause surface imperfections.

Spring and early fall often provide optimal weather conditions for epoxy installation, avoiding extreme cold or heat.

Proper surface cleaning and preparation should precede application, ideally when environmental conditions are stable.

Spring offers moderate temperatures and low humidity, ideal for epoxy flooring projects.

Maintaining stable environmental conditions during application enhances durability.

Proper surface prep during suitable weather ensures adhesion and longevity.

Ways to make Epoxy Floorings work in tight or awkward layouts.

Popular materials for Epoxy Floorings and why they hold up over time.

Simple add-ons that improve Epoxy Floorings without blowing the budget.

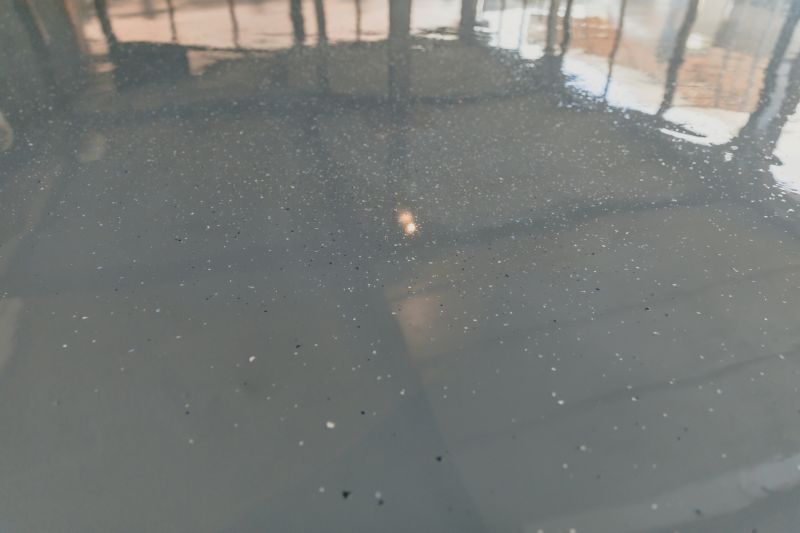

Epoxy flooring is a durable, versatile surface solution used in commercial, industrial, and residential settings. It provides a seamless, high-gloss finish that resists stains, chemicals, and abrasion. The installation process involves surface preparation, primer application, and multiple epoxy layers, each requiring specific environmental conditions for optimal curing. Proper timing of installation can significantly impact the longevity and appearance of the epoxy surface.

Application in suitable weather ensures a smooth, durable finish.

High-gloss, seamless surface with long-lasting performance.

Proper cleaning and priming are essential before application.

Ideal for warehouses, garages, and factories requiring tough surfaces.

High-end options that actually feel worth it for Epoxy Floorings.

Finishes and colors that play nicely with Epoxy Floorings.

Little measurements that prevent headaches on Epoxy Floorings day.

A 60-second routine that keeps Epoxy Floorings looking new.

A frequent mistake in Epoxy Floorings and how to dodge it.

Small tweaks to make Epoxy Floorings safer and easier to use.

Lower-waste or water-saving choices for Epoxy Floorings.

The short, realistic tool list for quality Epoxy Floorings.

| Factor | Recommended Conditions |

|---|---|

| Temperature | 60°F to 85°F |

| Humidity | Below 70% |

| Season | Spring or early fall |

| Weather | Dry, stable conditions |

| Surface Readiness | Clean and dry surface |

| Time of Day | Mid-morning to late afternoon |

| Project Duration | Multiple days for large areas |

| Environmental Stability | Avoid rain or extreme heat |

Scheduling epoxy flooring installation during optimal environmental conditions ensures the best adhesion, curing, and finish quality. Proper planning around weather patterns and seasonal changes minimizes the risk of defects and enhances the lifespan of the flooring surface. Consulting with professionals can help determine the most suitable timing based on specific project requirements.

Performed under optimal environmental conditions for best results.

Long-lasting finish achieved with proper timing.

Ensures consistent curing and high-quality finish.

Rough timing from prep to clean-up for Epoxy Floorings.

Quick checks and paperwork to keep after Epoxy Floorings.

Examples that show the impact a good Epoxy Floorings can make.

Interested in epoxy flooring installation? Filling out the contact form provides detailed information to assist with scheduling and project planning. Proper timing and preparation are key to achieving durable, high-quality epoxy surfaces that meet specific needs and expectations.